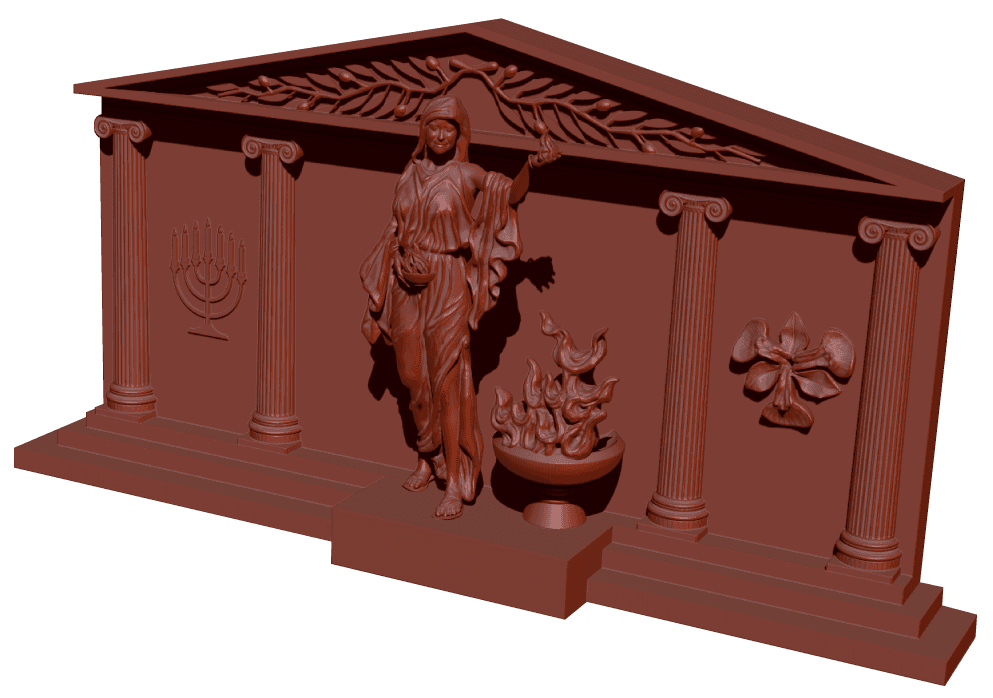

Complex 3D stonework manufacturing requires state-of-the-art robotics and equipment. Therefore, a very specialized programming expertise. The programming itself must be based on 3D scans and/or 3D drafting, using a range of leading design software.

Our initial stone sculpting specialty, lead us to develop complimentary areas of expertise as our scanning equipment and to in-house 3D drafting and modelling.

Each of these specializations may be used in the process of realizing final-end stone products, but may also serve independently to meet clients’ needs.

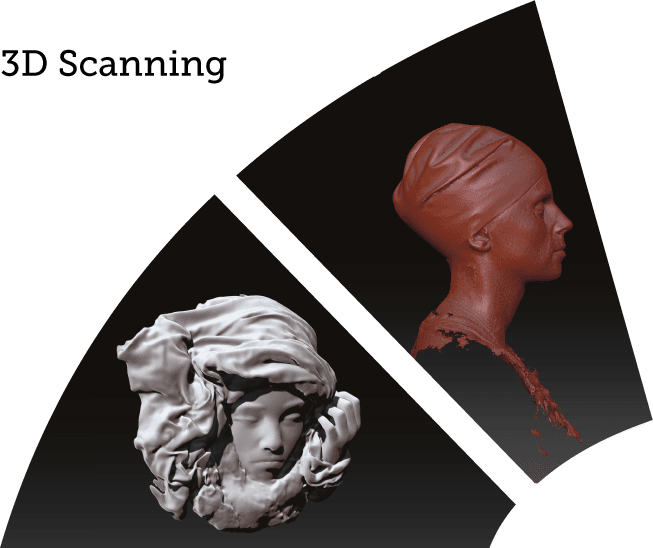

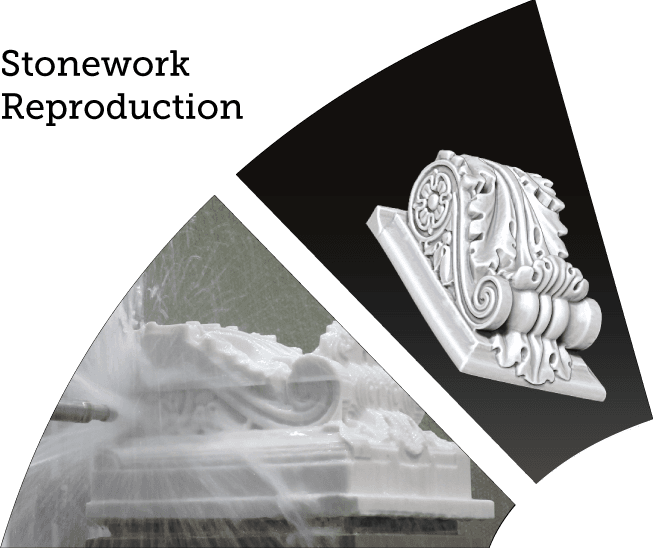

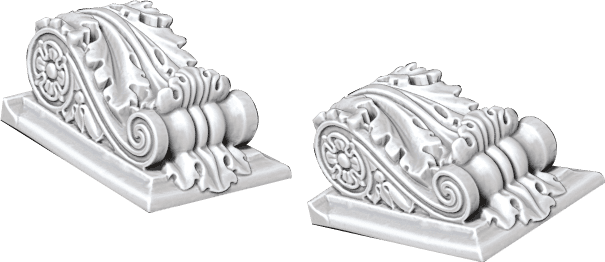

Our scanning technology is the most accurate way to ensure a perfect replica of any architectural or artistic element. The 3D scan’s aim is to create a virtual model out of a physical object. The acquisition of a computer-based model is the first step of the manufacturing process to completing a copy of the element.

Beside reproducing a stone object, our 3D scanning expertise can be used to digitalize elements with the intention of preserving them virtually, in their actual state.

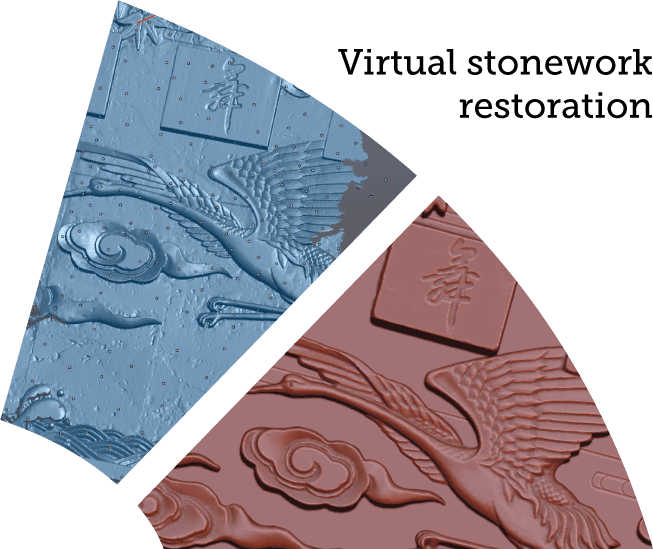

Virtual restoration is a computer-based methodology for the repairing of damaged artistic and architectural stone elements, remodeling them to their original condition, so before they were damaged.

Through this process, high-technology imaging, drafting, digital sculpting and 3D modelling software is used. If available, our graphic artists may refer to historical pictures of the objects to minimize biases in interpreting the repairs to be made.

The damaged object is restored to its original state. Cracks are repaired and missing sections are filled. The computer-based and restored 3D model is now ready to move into the next phases of production to achieve a perfect stone made replica of the physical object.

Our 5 and 8 axis robots analyze digital information, from both scans and design programs, to carve replicas of any object with an unmatched precision.

The elements to be

milled

with our robots may either be as small as a few inches in dimensions, or be oversized, up to 18 feet in overall dimensions. Whatever the object's size, the end accuracy of our robotics is generally of a quarter of a millimeter, an accuracy that could not be attainable by traditional handcrafting.

From the acquisition of the virtual copy of the physical object with our 3D scanners, we can modify the object's dimensions prior to its reproduction.

Whether the object's replica is smaller or larger than the original object, absolutely no details are ever lost. Details are only made smaller or bigger in the same established proportions.

The possibility of maximization is also interesting in that it allows the production of any artistic stonework from a base model made out of clay, plaster, or any other material.

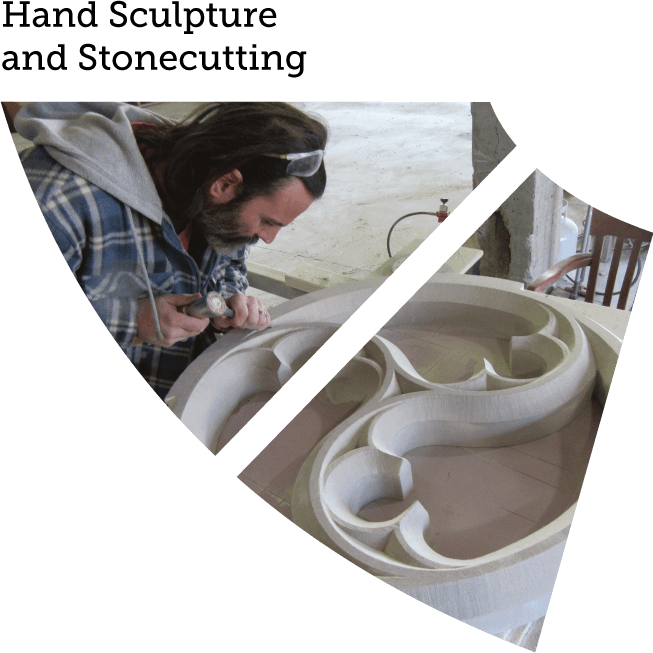

According to the technical characteristics of each project, our precision production equipment may either be used for processing as well as for the finishing phase, or the finishing phase may also be performed by hand.

Far from being set aside by technology, our team of sculptors and stone cutters are essential and complementary. Indeed, the process of realizing final-end 3D complex stone products involves artistic skills at many stages, as well as an intimate knowledge of the different types of stones.

Our niche so requires to have artistic trained professionals as members of our team.

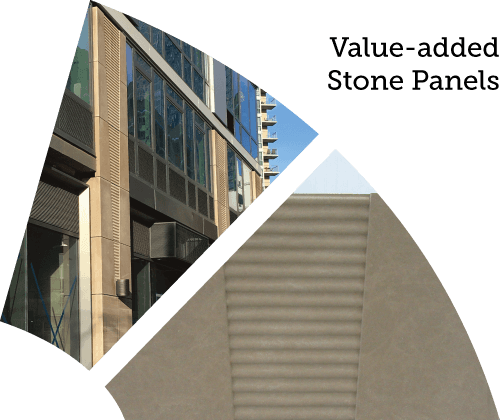

Even though our robots are designed to mill highly complex 3D stone elements, it is always possible for us to mass-produce pieces that do not necessarily require the full extent of our equipment's capacities.

Custom design on stone panels for cladding is one of our specialties, for we are able to achieve any unique pattern, sculpture or concept you have imagined for this one-of-a-kind building.